CHIPBOARD PANELS:

1.Type(Thickness:28mm; Density:720kg/m3): Humidity and temperature rates change in the climate. But there isn't

any stability changings, because this type of panel has a high density.

2.Type(Thickness:38mm; Density:780kg/m3): Fire and load

endurances of this type is more durable than 28mm panel.

CALCIUM SULPHATE PANELS:

This type of panel has 34 mm thickness and 60-90-120 minutes fire

endurance rates as requests. If the subcoating is made from

steel, fire endurance will be 60 minutes. Fire

endurance will be decreased, because steel is a heat transmitter.

COMPOSITE PANELS:

Composite Panels are produced to connect both 12.50 mm calcium sulphate

panel and 28 mm chipboard panel. Panel thickness

without plated is 40.50 mm and using in control rooms,

laboratories, etc.

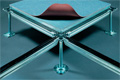

CONCRETE PANELS:

Panel thickness without plated is approximately 37mm. In the high

capacity, this type of panel has a high fire, loa and, humudity

resistances. Especially, it is preferred in

a high fire endurance buildings.

DOWN SURFACE COATING PROFILES

![]() 0.05 mm Aluminium Foil

0.05 mm Aluminium Foil

![]() 0.50mm Galvanized Steel

0.50mm Galvanized Steel

![]() 0.70mm Laminate(To practise as up surface is coated 1.0 mm laminated.)

0.70mm Laminate(To practise as up surface is coated 1.0 mm laminated.)

UP SURFACE COATING PROFILES AND TYPES:

![]() 0.05 mm Aluminium Foil

0.05 mm Aluminium Foil

![]() 0.50 mm Galvanized Steel

0.50 mm Galvanized Steel

![]() 0.50 mm Encapsulated Steel Panels(Subcoating, topping and borders are coated)

0.50 mm Encapsulated Steel Panels(Subcoating, topping and borders are coated)

![]() 1.0 mm HPL Laminate

1.0 mm HPL Laminate

![]() Vinyl

Vinyl

![]() Rubber

Rubber

![]() Linoleum

Linoleum

![]() Ceramics(60x60cm or 30x30cm)

Ceramics(60x60cm or 30x30cm)

![]() Natural Stone, Marble

Natural Stone, Marble

![]() 5mm Solid Wood Parquet

5mm Solid Wood Parquet

![]() Glass Panel

Glass Panel